Aerosols |

|

| An

aerosol is a system consisting of very finely divided liquid

or solid articles of dispersed in and filled by gas. In recent

years aerosols have become well known products discharged

from spray dispensers, and the term aerosol has, in popular

speech also come to means the dispenser itself i.e. a pressurized

container made of metal or glass and provided with a discharge

valve, which may be a spray valve or a foam valve. It is filled

with the product to be sprayed and the propellant gas under

pressure.

|

|

| The

aerosol can was invented in 1926 by Erik Rotheim. He invented

the first aerosol can and valve that could hold and dispense

products and propellant systems. This was the forerunner of

the modern aerosol can and valve. The patent was sold to a

US company for 100,000 Norwegian kroners, but it wasn't until

1941 that it was first put to good use by Americans Lyle Goodhue

and William Sullivan. They turned it into an instrument for

the US military to fight the malaria mosquito in the Pacific

during World War II. Aerosol spray products have three major

parts; the can, the valve and the actuator or button.

|

|

| The

term aerosol derives from the fact that matter floating in

air is a suspension i.e. a mixture in which solid or liquid

or combined solid-liquid particles are suspended in a fluid.

To differentiate suspensions from true solutions, the term

sol evolved originally meant to cover dispersions of tiny

particles in a liquid. With studies of dispersions in air,

the term aerosol evolved and now embraces liquid droplets,

solid particles, and combinations of these. An aerosol may

come from sources as various as a volcano or an aerosol can.

|

|

|

|

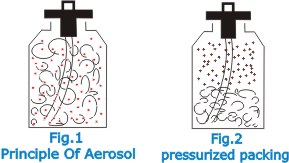

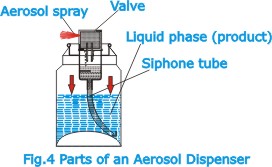

| The

product to be dispersed as an aerosol may have the liquefied

propellant mixed with it in the form of a solution (Fig.1).

Alternatively, the propellant may be present as a separate

gaseous phase in the dispenser, in which it does not mingle

with the product (two-phase system: Fig.2).

|

|

| An

example of the first type is afforded by hair spray. The spray

or lacquer, usually dissolved in alcohol, is completely miscible

with the liquefied propellant. When the valve button on the

dispenser is pressed, the propellant vaporizes immediately,

and its pressure forces the liquid out of the nozzle. The

liquid i.e., the lacquer solution is discharged as a fine

mist. The most commonly employed propellants are chlorinated

hydrocarbons, butane, propane, isobutane, vinyl chloride and

nitrogen. Nitrogen is used particularly for products that

on no account be contaminated in flavor or smell e.g., toothpaste

packaged in aerosol dispensers.

|

|

| |

|

| Aerosol

toothpaste is an example of the second category of aerosol

systems particularly, the two-phase system in which the propellant

gas forms a separate layer over the product to be discharged.

The dispenser is half milled with nitrogen or some other suitable

gas and half with the product. The pressure in the dispenser

is about 6 to 8 atm. (90 to 120 lb. /in2). Nitrogen can also

be used as the propellant for foods packaged in aerosol form

e.g., cheese spreads, malt extracts, vitamin preparations,

syrups, pudding sauces, whipped cream. |

|

|

|

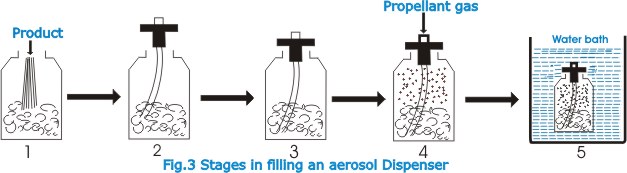

| Filling

an aerosol dispenser at the factory is a simple operation

(Fig.3: stages 1 to 5). First the product is introduced into

the dispenser. This is done by a pneumatic filling machine.

Then the aerosol valve is placed on the dispenser. In the

next stage the valve is force-fitted under high pressure into

the neck of the dispenser, so that a strong gastight seal

is formed between the latter and the valve unit. The propellant

gas is now forced into the dispenser. Finally, the dispenser

is immersed in water to test it for possible leakage, which

is manifested by escaping bubbles of gas. |

|

|

|

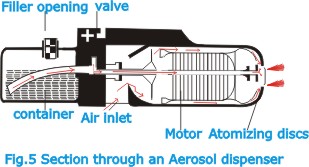

| Aerosols

are coming into increasingly widespread use in industry. They

are used for the disinfection of milk tanks. For this purpose

a spraying device is used which draws the disinfectant solution

by suction from a container and disperses it as an aerosol

by means of two atomizing discs. These discs rotate, and their

centrifugal action sets up a suction which draws the disinfectant

forward through the hollow shaft of the motor. |

|

|

|

| To

make the aerosol mist flow in the desired direction, a second

air stream is needed. A turbine is installed behind the motor

sucks in air, which flows along the motor and emerges from

the annular aperture around the atomizing discs. This stream

of air carries along the aerosol particles of disinfectant

(Fig.5). |

|

|

o

DISCLAIMER o

CONTACT US |