Copper

|

|

| Copper

was known to some of the oldest civilizations on record, and

has a history of use that is at least 10,000 years old. Most

copper is obtained from sulphide ores. These are found admixed

with large quantities of gangue and the initial content of

copper may be very low. A concentrate containing 15 to 35%

copper is produced by flotation. |

|

|

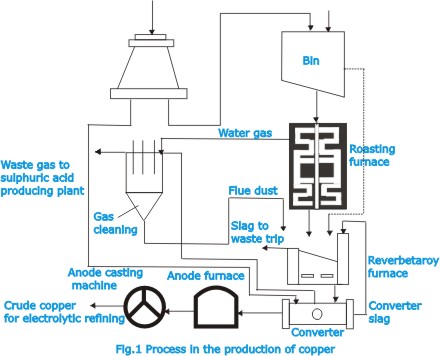

For

the purpose of eliminating some of the sulphur and certain

impurities, the concentrate is usually roasted before smelting.

Roasting is carried out in multiple-hearth furnaces, in which

oxidizing reactions take place: sulphur is eliminated as the

dioxide and metallic sulphides i.e. iron and some copper remain

behind as oxides.

|

|

|

|

| Copper

is essential for computers to work. Copper is used in building

the integrated circuits, chips, and the printed circuit boards

of the computer alone. Copper is becoming more and more popular

to use in the layers of the build-up of a chip. IBM announced

a plan to use copper in its computer chip rather than aluminum.

Doing so would make the computer to be cheaper and would allow

it to make faster calculations. And one more thing statue

of liberty is made of copper. It is green because the copper

has combined with carbon dioxide and water in the air. |

|

| Copper,

as native copper, is one of the few metals to naturally occur

as an uncompounded mineral. No one knows exactly when copper

was first discovered, but earliest estimates place this event

around 9000 BC in the Middle East. A copper pendant was found

in what is now northern Iraq that dates to 8700 BC. It is

probable that gold and iron were the only metals used by humans

before copper. |

|

|

|

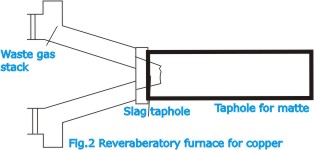

| The

mixture calcine contains the sulphides of iron and copper,

together with gangue material and impurities. The next step

consists in producing a molten artificial sulphide of copper

and iron, known as matte, containing all the copper and desired

amount of iron. For producing the matte smelting operation

is generally carried out in a reverberatory furnace (Fig.2)

fired with oil, natural gas or pulverized coal. |

|

|

|

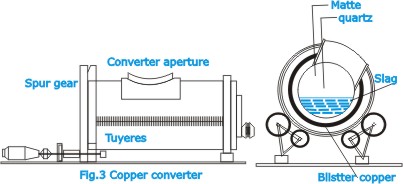

| The

charge is fed through the roof, and molten material collect

in a pool at the bottom. Slag, which rises to the top, is

tapped off. The matte collects at the bottom of the pool and

is discharged through a taphole. The molten matte is fed to

a converter (Fig.3) in which the iron and sulphur are removed

by oxidation, which is effected by blowing air through the

molten mass and is based on the fact that copper has a lower

affinity for oxygen than has iron or sulphur.

|

|

| The

reactions in the converter occur in several stages. First

the iron oxidizes and forms a slag with silica, which has

been added to the charge; this slag is tapped off, the copper

then being present as the sulphide. Further oxidation results

in the formation of metallic copper with a small amount of

copper oxide and other impurities. The converter in which

the process is performed is a large revolving refractory-lined

drum. |

|

| |

|

| The

copper obtained in the converter is subjected to further refining

treatment, which consist in fire refining (in furnaces) followed

by electrolytic refining. Fire refining is done in small reverberatory

furnaces or in revolving furnaces similar to the copper converter.

Air is blown through the molten material to oxidize all impurities;

the oxides rise to the surface and are skimmed off. This is

then followed by a reduction process which is performed by

forcing the ends of green logs into the molten metal to form

highly reducing gases. |

|

The

copper obtained as a result of this treatment is called tough

pitch. For further refining, it is cast into anodes for electrolytic

refining cells (Fig.4). The system most widely used is known

as the multiple system, comprising separate anodes and cathodes;

the latter consist of thin sheets of high-purity copper. When

an electric current is passed through cells, copper is dissolved

from the anodes and is deposited in a very pure form on the

cathodes. When these have grown to a thickness of about ½

inch they are replaced by fresh starting sheets. |

|

Ore

treatment may, alternatively, be carried out by hydrometallurgical

processes in which the ore is treated with a solvent that

dissolves the copper and leaves the undesirable material unaffected.

This principle is applied more particularly to the oxide ores

of copper, or to sulphide ores after suitable roasting, sulphuric

acid being used as the leaching solvent. Elaborate washing,

filtration and purification of the leach solution are associated

treatments.

|

|

| Copper

is essential in all plants and animals. Copper is carried

mostly in the bloodstream on a plasma protein called ceruloplasmin.

When copper is first absorbed in the gut it is transported

to the liver bound to albumin. Copper is found in a variety

of enzymes, including the copper centers of cytochrome c oxidase

and the enzyme superoxide dismutase (containing copper and

zinc). In addition to its enzymatic roles, copper is used

for biological electron transport. |

|

|

o

DISCLAIMER o

CONTACT US |