Foam Plastics |

|

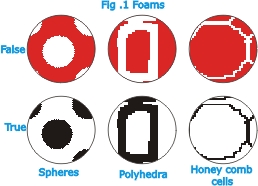

| One

of the basic features of foam-type materials is the structural

configuration of the cells. Absorbent cotton (cotton wool),

felt and glass wool, for example, do not belong to this category

of materials; sponges and cork, on the other hand, do. A difference

can be made between true and false foams. In true foam the

individual cells are not mere relatively thick-walled cavities

or pores, but are separated only by thin partitions and are

interdependent for their stability (Fig.1).

|

|

|

|

| The

mechanical strength is the highest in the case of foams with

closed (nonintercommunicating) cells. Since no convection

is possible in such materials, they possess good thermal insulating

capacity. With open (intercommunicating) cells the mechanical

strength and thermal insulation are lower; while, these materials

have a high sound-absorbing capacity and are therefore good

acoustic insulators.

|

|

|

|

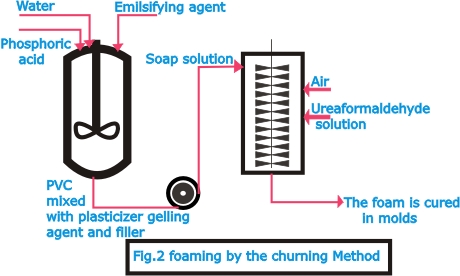

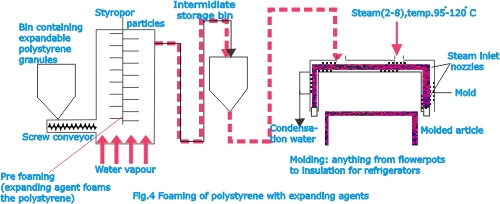

| Artificial

foam materials, including more particularly foam plastics,

can be manufactured by three different methods: by churning

(Fig.2), by expansion with chemical agents (Fig.4) and by

physical methods (Fig.3). The initial materials that can suitably

be processed into foams include polyvinyl chloride (PVC),

polystyrene, urea and formaldehyde condensation products,

and natural synthetic rubber. In the churning process of producing

foam rubber, latex to which fillers, vulcanization accelerators

and foaming agents i.e. surface-active substances have been

added is stirred with air to form foam, which sets and is

then vulcanized with hot air (Dunlop process).

|

|

|

|

|

|

| Urea-formaldehyde

foams are made by foaming a soap solution with an incompletely

condensed water-soluble resin resolution and air in an impeller-type

high-speed mixer. Further condensation is brought about by

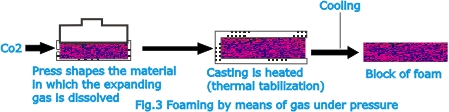

the addition of acid. In the process based on physical methods,

the foaming (expanding) action is produced by gases such as

nitrogen, carbon dioxide, or pentane. Gas dissolved in the

material under pressure is liberated from the solution and

thus forms bubbles in the material when the pressure is reduced;

this is the foaming action.

|

|

| For

example, PVC pastes are processed with carbon dioxide at a

pressure of about 20 atm. (300 lb. /in 2) and a temperature

between –5oC and 0oC. The fluid mass is passed into

the heating zone of the installation. Here the dissolved CO2

escapes and thus foams the material. The foam sets at a temperature

of 150 oC and is solidified by cooling. Polystyrene is foamed

with pentane, which is added at the polymerization stage e.g.,

in the manufacture of styropor.

|

|

| |

|

| Chemical

foaming methods are based on the fact that certain substances

will, on being heated, decompose and liberate gas, which forms

small bubbles i.e. foam cells. Azo compounds, N-nitroso compounds

and azides are employed as foaming agents. What all these

compounds have in common is that they liberate nitrogen when

they decompose. For the manufacture of polyurethane foam plastics

e.g., the German product named Moltopren, compounds containing

hydroxyl groups of high molecular weight are mixed with disocyanates

and water. |

|

|

The

foam plastic is formed according to the equation

|

|

| HO.R1.OH

+ OCN.R2.NCO ->… CO2.R1CO2.NH.R2NH.CO2.R1.CO2…

Surplus isocyanate groups react with the added water and CO2

is evolved, which acts as a foaming agent:

R-NCO + H2O -> R-NH2 +CO2

Isocyanate amine

|

|

| The

reaction mixture is cast in molds in which both the foaming

and the hardening process take place. Blocks of foam are cut

up into slabs or sheets by cutting machines.

|

|

| In

the building industry foam plastics have achieved importance

as heat and sound insulating materials. They are also used

for a number of other purposes e.g., as paddings, packing

materials, materials for the manufacture of sponges and bath

mats.

|

|

|

o

DISCLAIMER o

CONTACT US |