Steam Engine |

|

|

A steam engine utilizes the energy contained in steam under

high pressure. The energy that is released when steam expands

is made to produce rotary motion which can be used for the

driving of machinery.

|

|

|

Steam engines were first invented by Thomas Newcomen in 1705,

and James made big improvements to steam engines in 1769.

The Newcomen steam engine used the force of atmospheric pressure

to do the work. In 1712, Thomas Newcomen together with John

Calley built their first engine on top of a water filled mine

shaft and used it to pump water out of the mine.

|

|

|

|

|

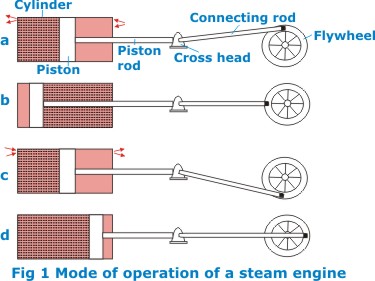

The steam from the boiler is admitted into the cylinder in

which there is a piston and in which the steam expands, causing

the piston to move (Fig.1a). When the piston has traveled

to the end of the cylinder and thus completed it does stoke

(Fig.1b), the now expanded stream is allowed to escape from

the cylinder.

|

|

| At

the same time the steam is changed over, live steam under

pressure being admitted to the other side of the piston, causing

the latter to travel back, past its starting point (Fig 1c),

until it has reached the other end of its stroke (Fig 1d).

A steam engine of this kind is called double-acting because

the force of the steam is applied alternatively on two sides

of the piston. While the piston is being forced in one direction

by the expanding stream, the spent stream is pushed out of

the cylinder on the other side of the piston.

|

|

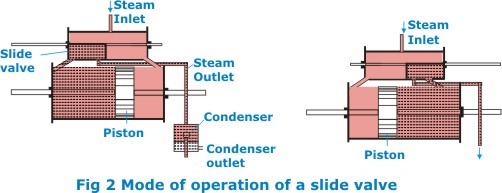

| The

change over of the steam supply to ensure the admission of

live steam to appropriate side of the piston and the discharge

of the spent steam on the other side, is effected automatically

by a control device called a slide valve. Some steam engines,

valves are similar in principle to those used in internal

combustion engines. The commonest type is the flat slide valve,

also called a D-slide valve (Fig.2).

|

|

|

|

| It

alternatively covers the steam inlet port and exhaust port.

During the piston movement the slide valve opens the exhaust

port for the escape of the spent stream behind the piston

(Figs. 2a and 2b). The slide valve must therefore always be

in such a position that it connects the working side of the

piston to the live steam supply, and opens the exhaust port

on the other side to enable the stream to escape into the

exhaust channel. |

|

|

| |

|

The valve performs this operation by moving to-and-fro at

the same rate as the piston. It is controlled through a linkage

system from the crankshaft such that the valve moves in the

opposite direction to the piston. The spent steam that emerges

from the cylinder is passed to a condenser where it is cooled

and thereby precipitated as water. In some cases it is, instead,

discharged direct into the atmosphere. |

|

|

The term compound steam engine refers to an engine in which

the steam is expanded in several cylinders usually three,

in successive stages. As a rule, all three pistons have the

same length of stroke, since they drive the same crankshaft.

However, as the volume of the steam increases as the result

of expansion, i.e., when its pressure is reduced, the second

or medium-pressure stage has a larger piston diameter than

the first stage or the high-pressure stage. The third or low

pressure stage has a piston of still larger diameter than

the second stage. |

|

|

The transmission of power and motion from the piston to the

crankshaft is effected through a crosshead i.e. a reciprocating

block sliding between guides which forms the junction piece

between the piston-rod and the connecting-rod. One end of

the latter is pivotally connected to the crosshead and other

end is connected to the circumference of a wheel or to a crank

of the crankshaft. When the piston, piston rod and crosshead

move to and fro, the crosshead transmits this movement to

the crankshaft or wheel and thus produces rotation. One end

of the crankshaft is provided with a fly wheel to ensure smooth

running, free from jerkiness due to the reciprocating motion

of the piston. |

|

|

Nowadays steam engines are used only in cases where the slow-running

machinery with varying power requirements has to be driven,

e.g. for winding gear in coal mines, ships propulsion machinery,

rollers, etc. Even the best steam engines have an efficiency

of only 15-18% in terms of utilization of the energy contained

in the coal. |

|

|

o

DISCLAIMER o

CONTACT US |